Engineered Feed and Sustainability

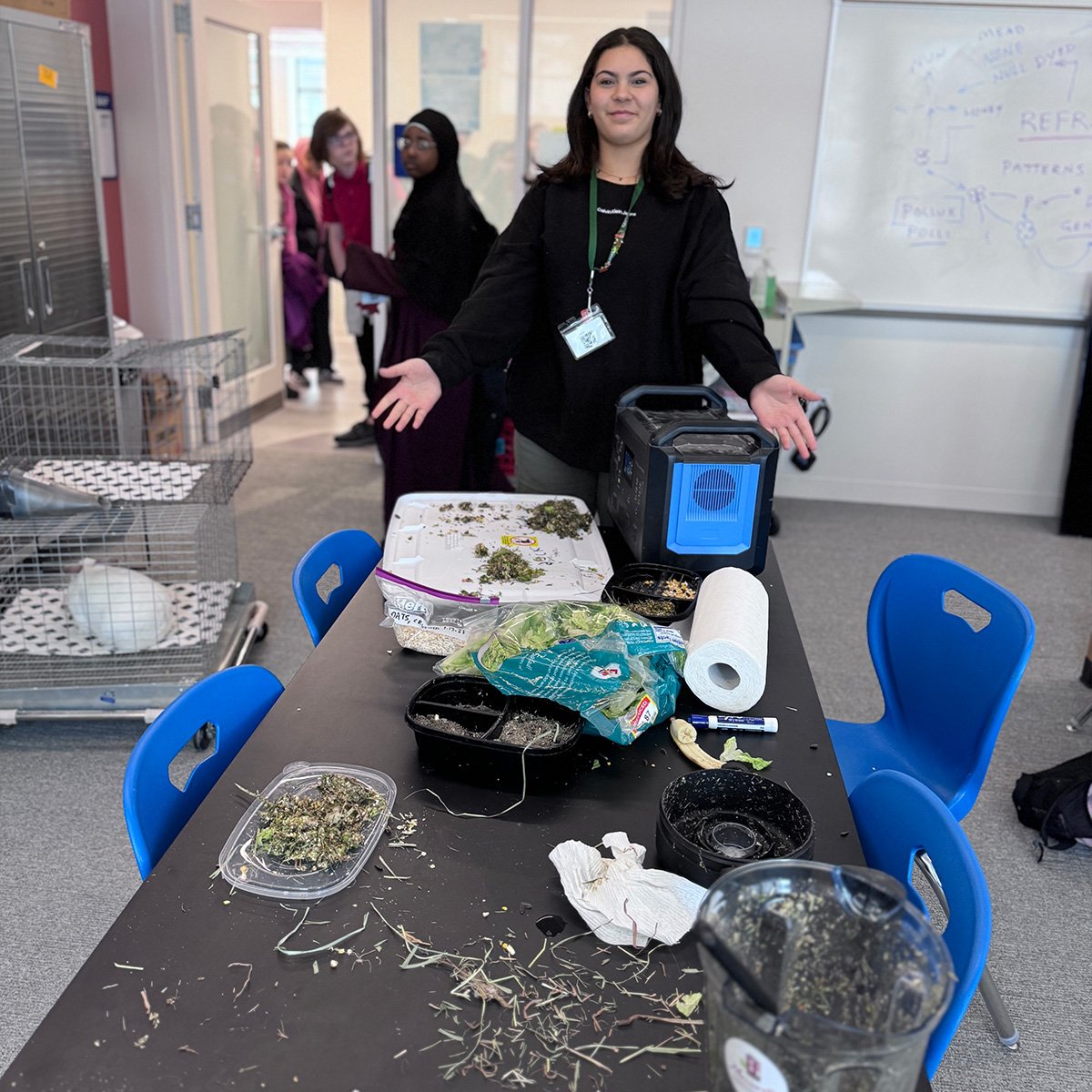

Behold, engineered nutrition

This is a blog about molecular nutrition and biological markers for different species of animals. Students were tasked to research what the nutritional value or footprint of each species required and then pull different grasses, grains, fruits, and liquids. Then they built a matrix that will be dehydrated and stored for use later. This is engineered feed and sustainability.

Once More With Data

For the last four days we have been exploring different species of livestock that live at Mezzacello Urban Farm at the new Metro Early College High School facility. The students are interacting with the animals and discovering how and when the animals interact with the ecology of Mezzacello.

Measuring and mixing raw ingredients to create $60 worth of feed for $12.83

Today, we explored feed, nutrition, performance, and their effects on animals. The students did some research on what the nutritional needs are of rabbits, chickens, and ducks. Then they created a matrix to show overlaps and unique indicators. When they had that documented, they chose different organic products to combine to create feed.

Time For Teamwork

I had the students self assemble into three groups (chromosomes) containing as much diversity in gender, culture, and friend groups as possible. They mixed the feed in the right ratios according to the matrix and the desired colric indexes and blended it all together. That data will be recorded and used later in packaging.

This blended food was then labeled and set aside. The kids understand that in this wet form, the nutrient dense feed is unstable and vulnerable to mold and bacteria that will transform the nutrients into waste. It must be dry-processed to make it shelf stable.

When the feed is properly dehydrated and packaged, it can be stored for use in winter, when green nutrient-dense plants are not as readily available. Tomorrow we will be exploring the realm of the molecule, atom, and quantum effects that allow animals to process and convert raw nutrients into molecular glucose.

Making Necessary Amendments

Before final packing is complete they will be adding additional nutrients and amendments to the dehydrated mix to create a smooth slew that when dehydrated again and mixed with molasses and cornstarch will create a mix to add to the pelletizer (a machine that extrudes pellets for feed from a mash). From that pellets of feed that are perfectly balanced for each species of animal will be bagged. These will be shelf stable and ready for use.

Then they will be designing packaging and user instructions for their new product. Stay tuned to see how it all turns out.

Is this a minecraft rabbit? Does this rabbit eat bricks?